A new era of food safety

It has taken many years of hard work but Taran Skjerdal,

The

- It has come to a point where we know we have something. The principle works - the method is so far not validated, but we are very optimistic that it will be, says Taran.

- We are on the path to designing the kit - red or blue, bag or box, the actual design. So we are waiting for the validation. We are about to complete a patent proposal, and, as far as I know, there is interest in

Taran says that over the years the Norwegian Veterinary Institute (NVI) has had many discussions with the various Norwegian food authorities and the reference laboratory network in Europe about Listeria. The main problem for all companies working in the food production chain, from the first day of processing to the supermarket, is knowing exactly how much Listeria is present.

- The challenge with Listeria is the ‘limit value’ - the amount of Listeria that is allowed in foods at the end of shelf life, says Taran. She continues:

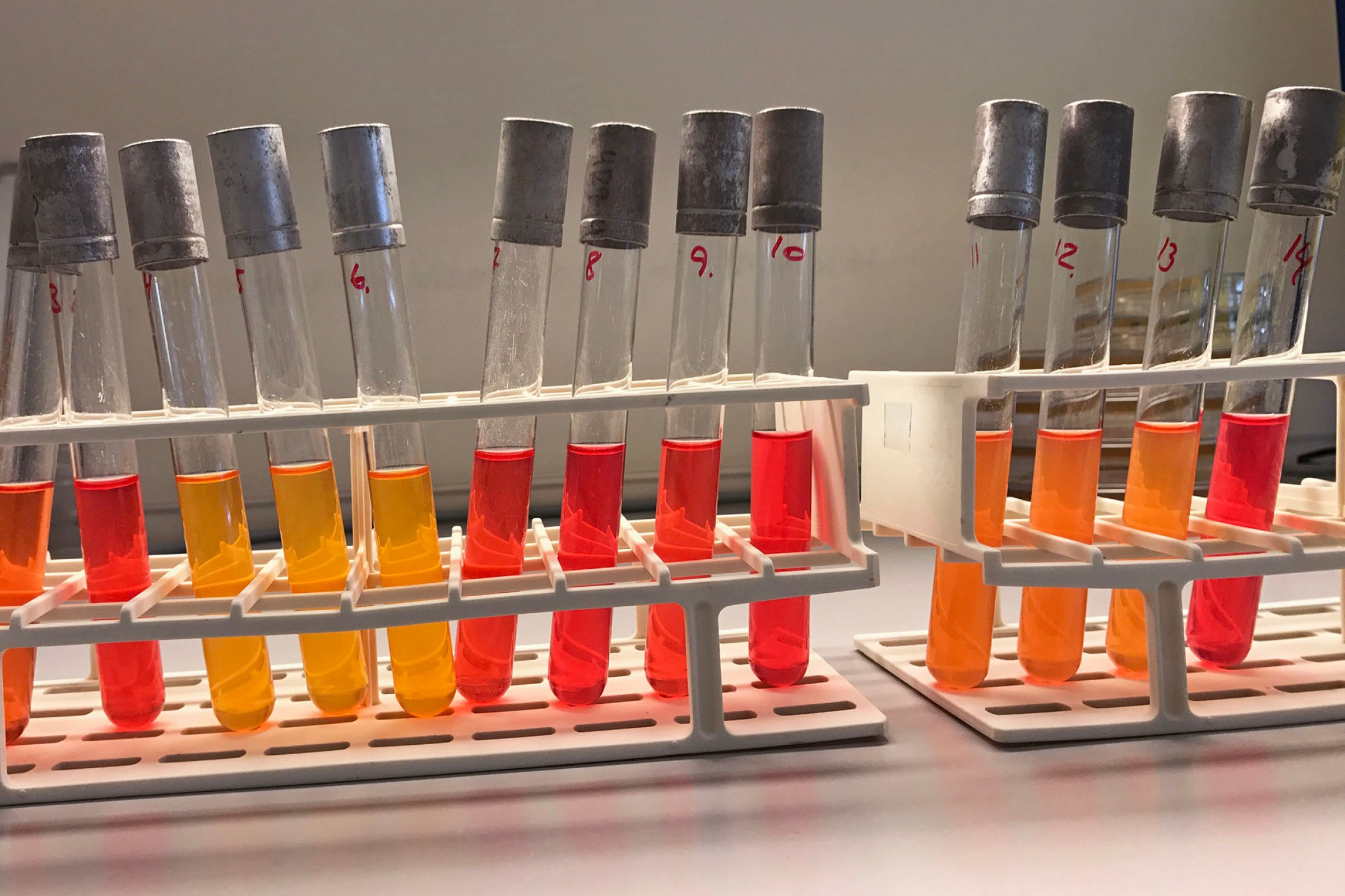

- If you think of Listeria in units of 1 to 100 per

The story began around

- I was lucky to be working in the seafood area, and then more lucky that we got to collaborate with a large company which had Listeria in its facilities, despite all their efforts to get rid of it

So if major food producers, despite their best intentions, cannot beat the Listeria problem, presumably they must be crying out for such a solution? Taran replies:

- Well, companies could say, there are other methods out there, why bother - and that is true - but our method is better. It is better because it doesn’t give so many false positive results and because it is quantitative in the range you need it, the range where we can provide the sensitivity. What we provide is a method that is easy to use and gives accurate information within that area, which is what is needed.

And with so much focus today on recycling, energy efficiency and ending waste, SensiList could usher in changes that are meaningful for both industry and the consumer.

- Listeria will be easier to detect - that is one side of it that maybe the consumer is interested in. But for a big company, when you take one sample and it is positive for Listeria but you don’t know how much is

- So now they can say, ‘We see we have Listeria here, but we can still sell it’. It is the balance between safe enough for the consumer and safe enough for the company. Even though we’re in Norway, a small part of the world, I think it is fair to say that with all the salmon we export abroad, it is also a possible supply of Listeria to the world. Therefore that is one reason to take responsibility. And in the bigger picture, Listeria can be in any food, anywhere, so all countries will have the same challenges, says Taran.